On the modern market of measuring instruments, a large number of different types and models of pressure gauges are presented. As instruments for measuring the pressure of liquids and gases, manometers are widely used in a wide variety of technical systems. In order not to be mistaken in choosing a device, you need to have a good idea of what purposes you need it for.

Instructions

Step 1

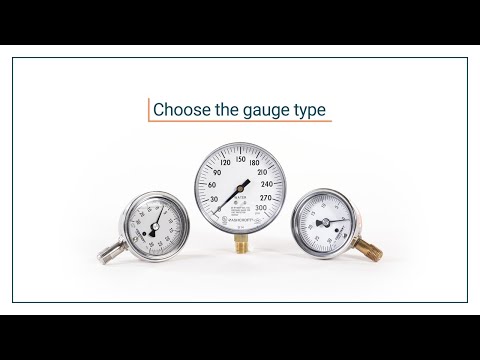

Determine the type of appliance you need. To measure pressure, the actual manometers, manovacuum meters, vacuum meters, as well as low pressure devices are used. Most of them are designed for gauge pressure measurement under special conditions. Devices of the same type are usually made according to a common standard and are therefore interchangeable.

Step 2

Find out in which pressure range the device will operate. This will require data on the operating pressure in the system that the pressure gauge will serve, and on the range of possible values. Add 25-30% to the working pressure, and you will get the desired characteristic, which must correspond to the manometer you are purchasing.

Step 3

When choosing, take into account the nature and characteristics of the environment in which the device is to be operated. It can be air, water, steam, oxygen and its varieties, acetylene. In such cases, general technical manometers will be needed.

Step 4

When purchasing a device for measuring pressure in oxygen, keep in mind that oxygen pressure gauges are more capricious and require additional care and maintenance (degreasing). In some cases, pressure measurement can be carried out in aggressive media (ammonia, chlorine, etc.); for such conditions, special devices that are resistant to the environment will be needed.

Step 5

Determine the required diameter of the meter body. If conditions permit a safe distance to the gauge, install a medium gauge. With relative inaccessibility, it is more convenient to take readings from a device with a significantly larger diameter. The diameters of standard devices range from 40 to 250 mm.

Step 6

Each pressure measuring device also has its own accuracy class: from 0, 15 to 4. The lower this indicator, the more accurate the device. Select the required accuracy in accordance with the characteristics of the system to be monitored. It makes no sense to purchase a high-precision pressure gauge if, according to the conditions, the pressure can vary over a sufficiently wide range. High accuracy is usually required for some research projects.

Step 7

If you plan to use a pressure gauge in a specialized production (for example, in the food industry), then you will probably need a device with media separators. For an accurate choice, consult a specialist, indicating the type and characteristics of the environment in a particular production.